Mechanical Engineering Training in Manchester: Skills Shaping Careers in 2026

Mechanical engineering training in Manchester is increasingly described in relation to emerging technologies and evolving industry needs. This article explores how training programmes commonly associated with mechanical engineering are presented for 2026, with attention to areas such as 3D printing, robotics, and sustainable design. It explains how skill development is typically structured, how practical and theoretical elements are combined, and why these competencies are often highlighted when discussing future-oriented engineering education. The content is purely informational and aims to clarify how skills are shaped through training, without implying guaranteed career outcomes, qualifications, or employment results.

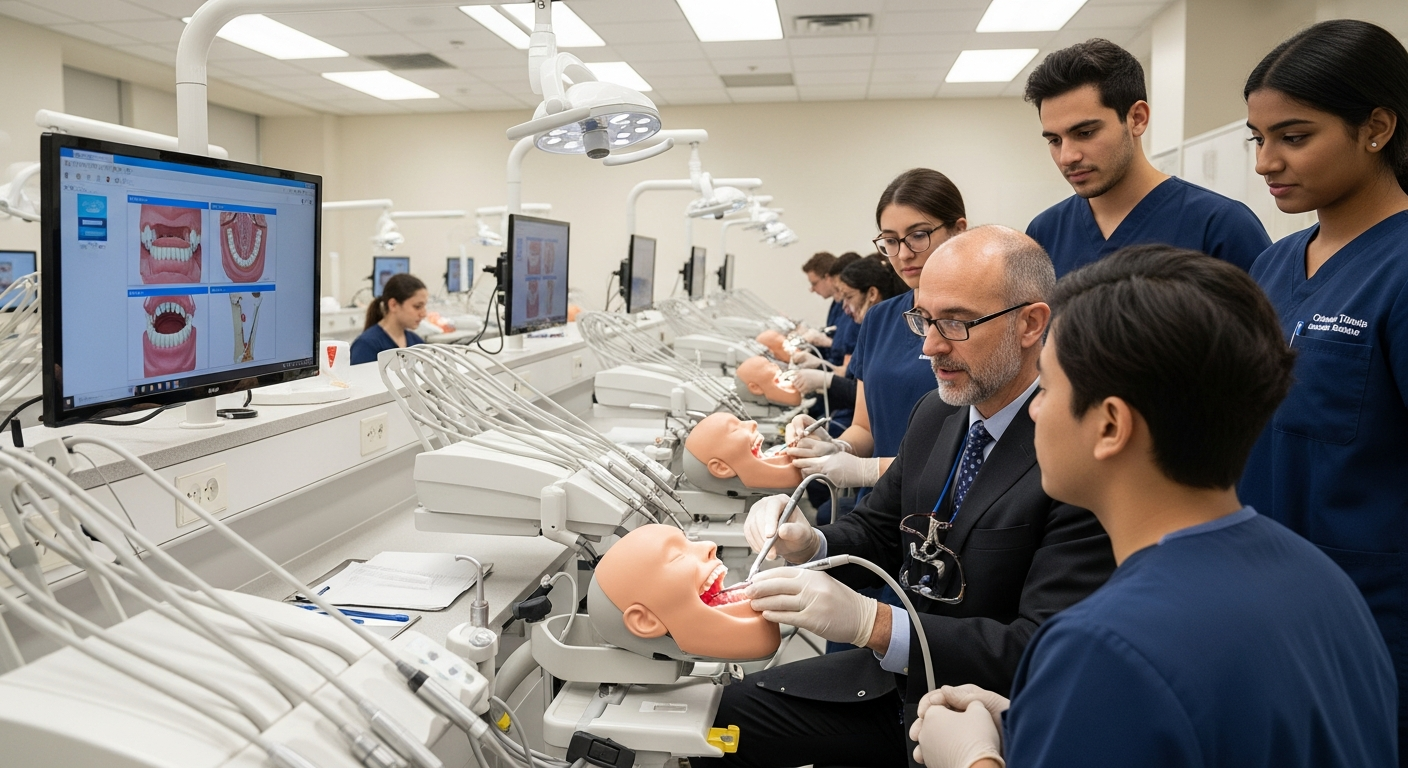

The mechanical engineering sector continues to transform, with Manchester emerging as a significant hub for innovative training approaches. Educational institutions and training centres throughout the city are adapting their curricula to address the evolving needs of modern engineering practice, ensuring graduates possess both foundational knowledge and contemporary technical skills.

Overview of Mechanical Engineering Training as Presented for 2026 in Manchester

Mechanical engineering training in Manchester encompasses a broad spectrum of educational pathways, from apprenticeships to advanced degree programmes. Universities, technical colleges, and private training providers collaborate with local industries to create comprehensive learning experiences. These programmes typically span two to four years, depending on the qualification level, and emphasise both academic rigour and practical application.

Training providers focus on core mechanical principles including thermodynamics, materials science, fluid mechanics, and structural analysis. Students engage with computer-aided design software, manufacturing processes, and quality control systems that reflect current industry standards. Many programmes incorporate work placements with Manchester-based engineering firms, providing real-world experience alongside classroom learning.

Focus on Emerging Technologies Such as 3D Printing Robotics and Sustainable Design

Contemporary mechanical engineering training increasingly emphasises emerging technologies that are reshaping the industry. 3D printing, also known as additive manufacturing, features prominently in modern curricula. Students learn to design components for additive processes, understand material properties specific to 3D printing, and explore applications ranging from prototyping to production manufacturing.

Robotics integration represents another crucial training component. Programmes cover robotic system design, automation principles, and human-machine interfaces. Students work with industrial robots, learning programming languages and safety protocols essential for modern manufacturing environments. Collaborative robots, or cobots, receive particular attention due to their growing presence in flexible manufacturing systems.

Sustainable design principles permeate modern engineering education. Training covers lifecycle assessment, renewable energy systems, and environmentally conscious material selection. Students explore circular economy concepts, waste reduction strategies, and energy-efficient design methodologies that align with global sustainability goals.

Structure of Skill Development Combining Theoretical and Practical Elements

Effective mechanical engineering training balances theoretical understanding with practical application. Classroom instruction covers fundamental engineering principles, mathematical modelling, and scientific concepts that underpin mechanical systems. Students engage with complex problem-solving scenarios, learning to apply theoretical knowledge to real-world challenges.

Laboratory work and workshop sessions provide hands-on experience with tools, machinery, and measurement equipment. Students practice machining operations, welding techniques, and assembly procedures while developing safety awareness and quality consciousness. Computer simulation software allows exploration of system behaviour under various operating conditions without physical constraints.

Project-based learning integrates multiple skill areas, requiring students to design, analyse, and potentially build mechanical systems. These projects often involve interdisciplinary collaboration, reflecting modern engineering practice where mechanical engineers work alongside electrical, software, and systems specialists.

Competencies Commonly Highlighted in Future Oriented Engineering Education

Modern mechanical engineering training emphasises competencies that extend beyond traditional technical skills. Digital literacy receives significant attention, with students learning to work with cloud-based design platforms, data analysis tools, and digital manufacturing systems. Understanding of Industry 4.0 concepts, including Internet of Things applications and cyber-physical systems, forms part of contemporary curricula.

Communication skills development recognises that engineers must effectively convey technical information to diverse audiences. Training includes technical writing, presentation skills, and collaborative project management. Students learn to document design processes, create technical reports, and participate in multidisciplinary team environments.

Adaptability and continuous learning capabilities receive emphasis, acknowledging the rapid pace of technological change. Training programmes encourage curiosity, critical thinking, and self-directed learning habits that enable professionals to evolve throughout their careers.

Informational Perspective on How Training Shapes Engineering Skills

Mechanical engineering training fundamentally shapes how practitioners approach problem-solving and system design. The combination of theoretical grounding and practical experience develops analytical thinking patterns that engineers apply throughout their careers. Students learn to break complex problems into manageable components, evaluate multiple solution approaches, and consider broader system implications.

Training experiences also influence professional identity and ethical awareness. Programmes typically include discussions of engineering responsibility, safety considerations, and societal impact of engineering decisions. This foundation shapes how graduates approach their professional roles and contribute to engineering teams.

The integration of emerging technologies during training periods influences career trajectories and specialisation choices. Exposure to robotics, sustainable design, or advanced manufacturing during education often determines areas of professional focus and ongoing skill development.

| Training Provider | Programme Duration | Key Technologies Covered | Estimated Annual Cost |

|---|---|---|---|

| University of Manchester | 3-4 Years | CAD, Robotics, Sustainable Design | £9,250-£28,000 |

| Manchester Metropolitan University | 3-4 Years | 3D Printing, Automation, Materials | £9,250-£26,000 |

| The Manchester College | 2-3 Years | Manufacturing, Quality Control | £3,000-£8,000 |

| Private Training Centres | 6-18 Months | Specialised Skills, Certification | £5,000-£15,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Mechanical engineering training in Manchester continues evolving to meet industry demands while maintaining strong foundational principles. The integration of emerging technologies, emphasis on sustainability, and focus on practical skills development ensures graduates are well-prepared for diverse engineering careers. As technology advances and industry needs shift, training programmes adapt to provide relevant, comprehensive education that serves both individual career aspirations and broader economic development goals.